Now that the most difficult part of the project is done, we can start soldering all other components to the board.

Take a look at my little workbench where I have all the tools I need to put the kit together.

To save space on the board, all resistors, inductors and capacitors are mounted vertically. I’m using a my round tweezers to bend the leads. This way they are all bent the same way.

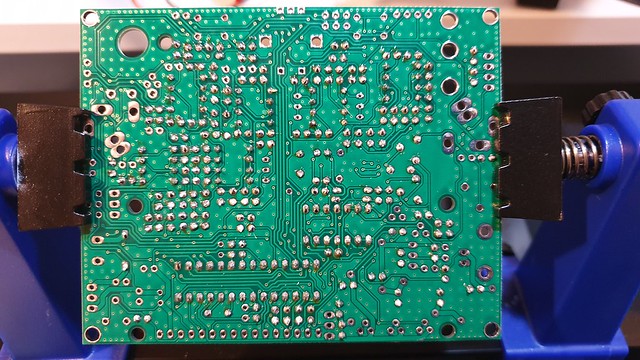

every component, and every soldering was checked after soldering. For this I use a magnifying glass for the visual check and a multimeter to check the connection.

Some of the tools I used for this project can be found on AliExpress.

The AN8008 Multimeter.

40X Full Metal Jewelers Folding Magnifying Glass with LED.

Set of precision tweezers.

PCB assembly stand.

Heat resistant and anti static silicone soldering pad.

Side cutting pliers.